Lasers emit concentrated beams of light that leave permanent marks on surfaces. Laser marking machines come in a variety of types, such as fiber lasers, pulsed lasers, continuous wave lasers, green lasers, and ultraviolet lasers. Lasers are used for a number of things, such as:

- Introducing

- Migration of carbon dioxide

- Research

- Embroidery is what I’m doing

- Infuriating

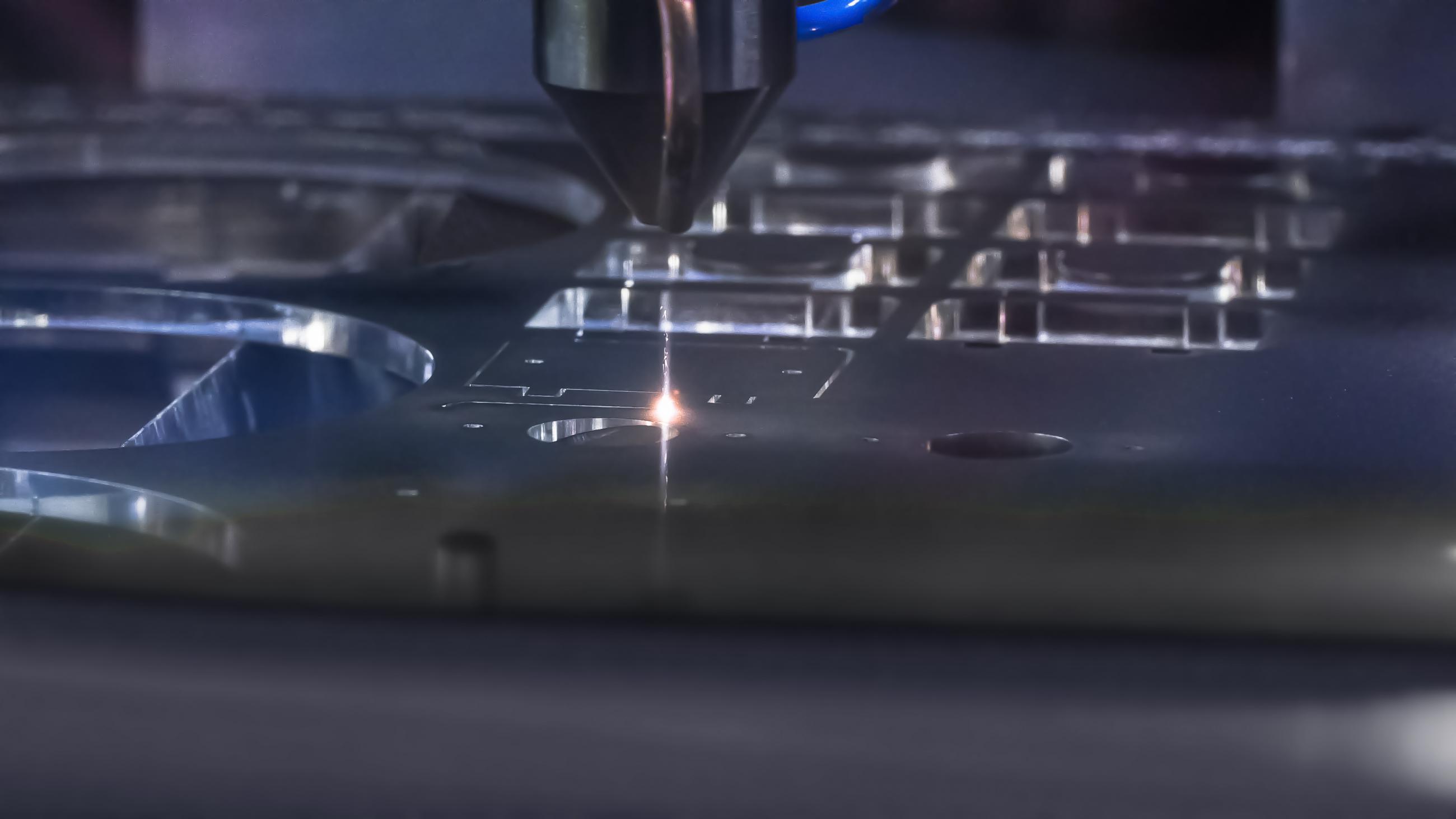

Besides being automated, processed at high speeds, and automated, laser marking can leave permanent traces on a variety of materials, including steel, titanium, aluminum, copper, ceramic, plastic, glass, wood, paper, and cardboard. A product or part can be identified by text (such as serial numbers and part numbers), by machine-readable information (such as barcodes, Unique ID codes, and 2D Data Matrix codes) or by graphics.

Table of Contents

Find Out About Laser Marking In 5 Minutes

A laser beam marks the surface of a material by using a focused beam of light. Through interaction with the surface, the beam changes the properties and appearance of the material. Laser marking machines produce marks of high quality, high contrast on virtually any surface because of this concentrated beam. As a result, laser marking is ideally suited for applications that need high degrees of precision and permanence.

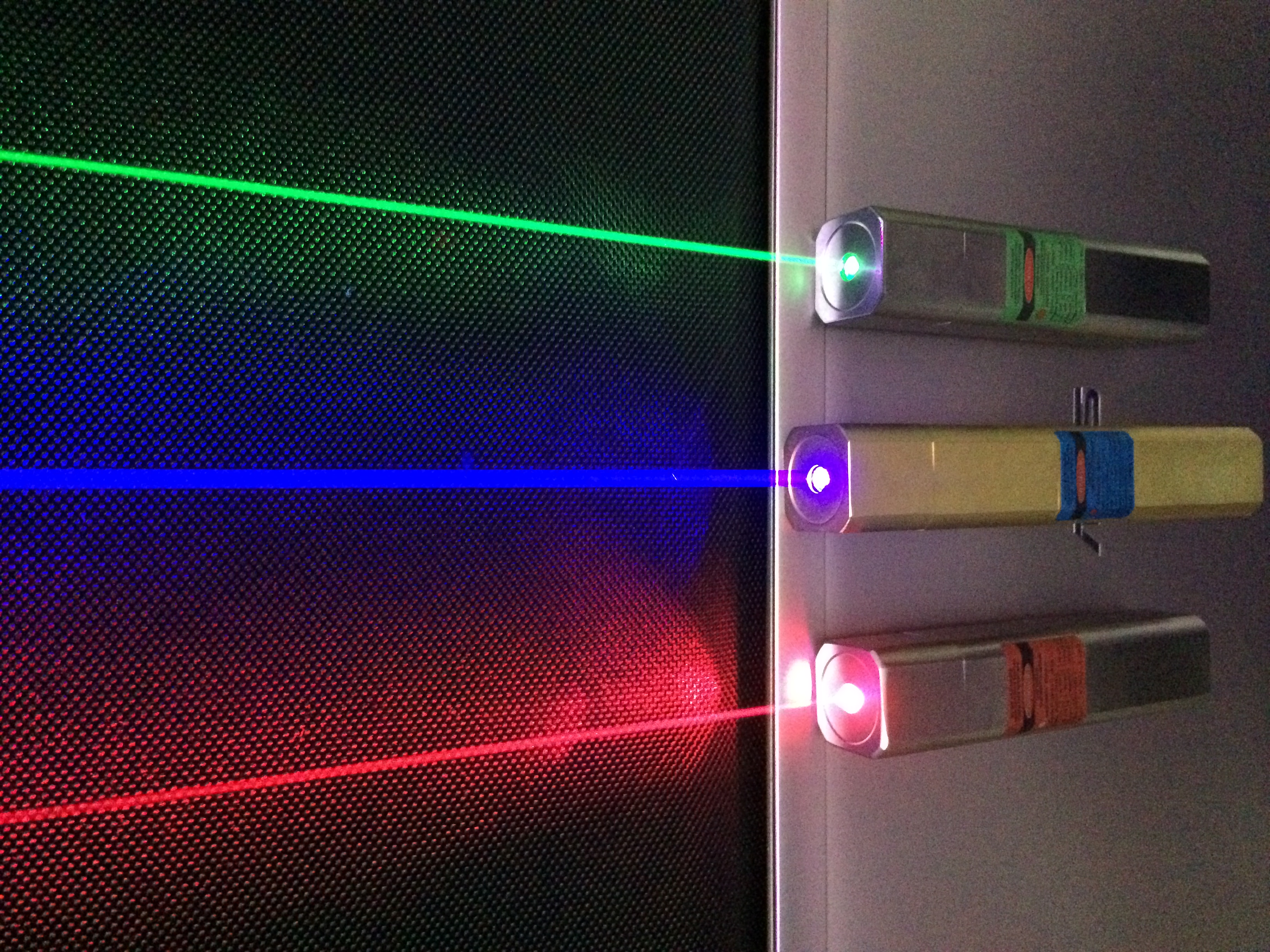

What Lasers Are All About

A laser is an instrument devoted to enhancing light through stimulating emission of radiation. Light particles are released when an atom is stimulated to emit light. Laser markers are made by concentrating this light. Nanometers, the unit of measuring energy released, stand for nanometers. The longer the wavelength, the more power is released.

The UV lasers, which have a wavelength of 355nm, are more effective at marking heat-sensitive materials such as plastic and glass. UV lasers are less likely to burn organic or soft materials, since they emit less energy than traditional lasers. Marking harder materials, such as metal, is easier with the 1070NM fiber laser.

Laser marking requires no consumables or maintenance, as opposed to other non-permanent marking methods such as printing or labeling. Apart from offering two-hour response times and free marking samples, our team also provides maximum uptime and system productivity.

The Laser Marking Machines Guide

Laser marking systems come in several kinds and operate differently. A machine’s material and application are also important to understand, as well as how it is used. The MECCO site includes how-to videos and detailed documentation, as well as resources to assist you with operating your machine and troubleshooting any problems.

Using a laser marking machine safely requires following all safety guidelines. Due to the availability of various preventative measures, such as safety enclosures, laser marking is relatively safe.

Laser Markers Provide Many Benefits

A manufacturer can use it in several ways, from basic identification to brand recognition, as well as complete traceability, which allows them to track and trace parts throughout the entire production process. A laser marking machine produces durable, readable marks when marking parts directly. Among the benefits of laser marking are:

- By reducing waste and downtime, operations are more efficient and productive

- Transparency and accountability in the supply chain would be beneficial

- A reduction in counterfeiting and an improvement in quality

- Conformed to industry regulation