As the construction and building industries continue to evolve, the demand for innovative, sustainable, and high-performance materials has never been greater. One material that is rapidly gaining popularity due to its exceptional properties is GRP (Glass Reinforced Plastic) flooring panels. These advanced panels are not only durable and versatile but also environmentally friendly, making them a top choice for modern building projects. In this article, we will explore why GRP flooring panels are at the forefront of flooring solutions, driving change in the construction industry and setting new standards for performance and sustainability.

Table of Contents

What Are GRP Flooring Panels?

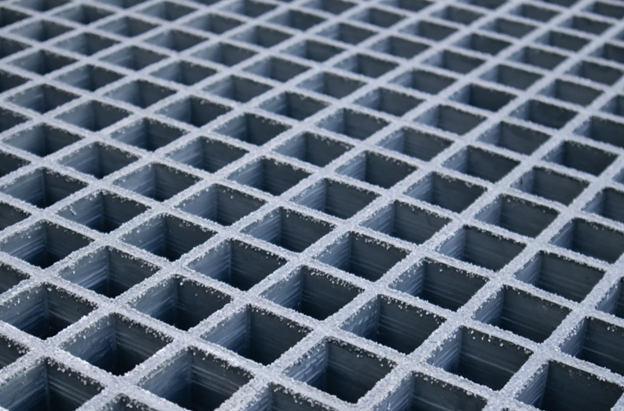

GRP panels are composite materials made by combining glass fibres with a resin matrix, typically polyester or epoxy, to create a robust and lightweight flooring solution. The glass fibres give the panels their strength, while the resin provides durability and resistance to various environmental factors. These panels are designed to offer superior performance in a wide range of applications, from industrial and commercial spaces to residential projects. Their unique combination of strength, flexibility, and resistance to corrosion makes them an ideal flooring solution for both interior and exterior environments.

Sustainability at the Forefront

One of the most compelling reasons why flooring panels are leading the charge in modern building materials is their sustainability. As the world becomes more focused on reducing its environmental impact, the construction industry is under increasing pressure to adopt materials that are not only high-performing but also eco-friendly. GRP panels meet these demands in several key ways.

Firstly, GRP panels are made from materials that are largely recyclable. The resin used in the panels can be recycled, reducing the amount of waste generated by the flooring installation process. Furthermore, the production of GRP panels requires less energy compared to other traditional materials like concrete or metal, contributing to a reduction in the overall carbon footprint of a building project.

Additionally, GRP panels are designed to last for decades without requiring frequent repairs or replacements. Their durability means that they don’t need to be replaced as often as other types of flooring, such as timber or tile, which reduces waste over the long term. Moreover, GRP flooring panels are resistant to a wide range of environmental stresses, including moisture, chemicals, and temperature fluctuations, making them ideal for environments where other flooring materials would degrade more quickly.

Superior Durability and Performance

GRP panels are renowned for their impressive durability, which is a crucial factor in their increasing popularity. These panels are resistant to various forms of damage, including scratches, dents, and impacts, which makes them ideal for high-traffic areas or industrial environments where other flooring materials would wear out quickly. Their ability to withstand harsh conditions, such as high moisture levels, extreme temperatures, and exposure to chemicals, means they are a reliable choice for both indoor and outdoor applications.

Unlike traditional flooring materials like wood or concrete, GRP panels are impervious to water and won’t warp, rot, or swell when exposed to moisture. This makes them an excellent option for wet environments, such as factories, warehouses, and bathrooms, where moisture-resistant flooring is a necessity. Additionally, flooring panels are non-slip, which makes them a safer choice for areas where safety is a top priority, such as hospitals, kitchens, or factories with high foot traffic.

The long lifespan of flooring panels also contributes to their sustainability and cost-effectiveness. While the initial investment in GRP panels may be higher than some traditional materials, their longevity and low maintenance requirements make them a more cost-effective option over time. The need for frequent repairs and replacements is significantly reduced, resulting in lower overall maintenance costs.

Versatility Across Multiple Applications

Another key advantage of flooring panels is their versatility. These panels can be used in a wide variety of settings, from commercial and industrial spaces to residential homes. In industrial environments, flooring panels are particularly valuable for applications that require high durability and resistance to chemicals, oils, or heavy machinery. They are often used in factories, warehouses, and production facilities where traditional flooring would not stand up to the demands of the environment.

For commercial applications, GRP flooring panels offer an attractive and functional solution for spaces that require both aesthetic appeal and performance. Their sleek appearance can be customised to suit a variety of design styles, making them a popular choice for retail spaces, offices, and public buildings. The flexibility of flooring panels in terms of colour, texture, and finish allows architects and designers to create unique, high-quality flooring solutions that meet both aesthetic and practical needs.

In residential applications, flooring panels are increasingly being used in bathrooms, kitchens, and outdoor spaces. Their water-resistant properties make them an ideal choice for areas that are frequently exposed to moisture, such as showers or patios. Furthermore, the panels are easy to clean and maintain, making them a practical choice for homeowners looking for a low-maintenance flooring solution.

Ease of Installation

GRP panels are designed to be easy to install, which adds to their appeal in both commercial and residential projects. Unlike traditional flooring materials such as concrete, which can require complex installation processes, flooring panels are relatively simple to fit and can be installed with minimal disruption to the existing space. The panels are lightweight and can be cut to size on-site, allowing for faster installation and reducing the overall time required for the flooring project.

Additionally, flooring panels do not require a complex subfloor preparation process, which can often add time and cost to a flooring installation. This makes them an attractive option for businesses or homeowners looking to complete a project quickly and efficiently. The ease of installation also contributes to the material’s cost-effectiveness, as it reduces the need for specialist labour and additional materials.

Resistance to Corrosion and Maintenance

One of the standout qualities of GRP flooring panels is their resistance to corrosion. Unlike metals or other materials that can rust or degrade when exposed to chemicals, GRP panels remain intact and functional in harsh environments. This makes them an excellent choice for environments that require exposure to corrosive substances, such as chemical processing plants, laboratories, or manufacturing facilities.

In addition to their corrosion resistance, GRP f panels are also low-maintenance. They do not require sealing, polishing, or regular treatments to maintain their appearance or functionality. This is in stark contrast to traditional flooring options such as timber, which may require refinishing or resealing over time to preserve their condition. GRP panels simply need to be cleaned with a mild detergent and water, making them an ideal solution for spaces where cleanliness and hygiene are a priority.

Conclusion

As we look towards the future of flooring solutions, it’s clear that GRP flooring panels are leading the way in sustainable, high-performance building materials. Their combination of durability, versatility, and eco-friendly properties makes them an ideal choice for a wide range of applications, from industrial settings to residential projects. With their long lifespan, low maintenance requirements, and ability to withstand harsh environments, flooring panels are not only a smart investment for businesses and homeowners but also a significant step towards creating more sustainable buildings for the future.

As the construction industry continues to prioritise sustainability and performance, GRP panels will undoubtedly play a central role in shaping the materials of tomorrow. Whether for industrial, commercial, or residential use, these panels offer a flooring solution that combines strength, functionality, and environmental responsibility, ensuring their place as one of the most advanced building materials of the modern age.